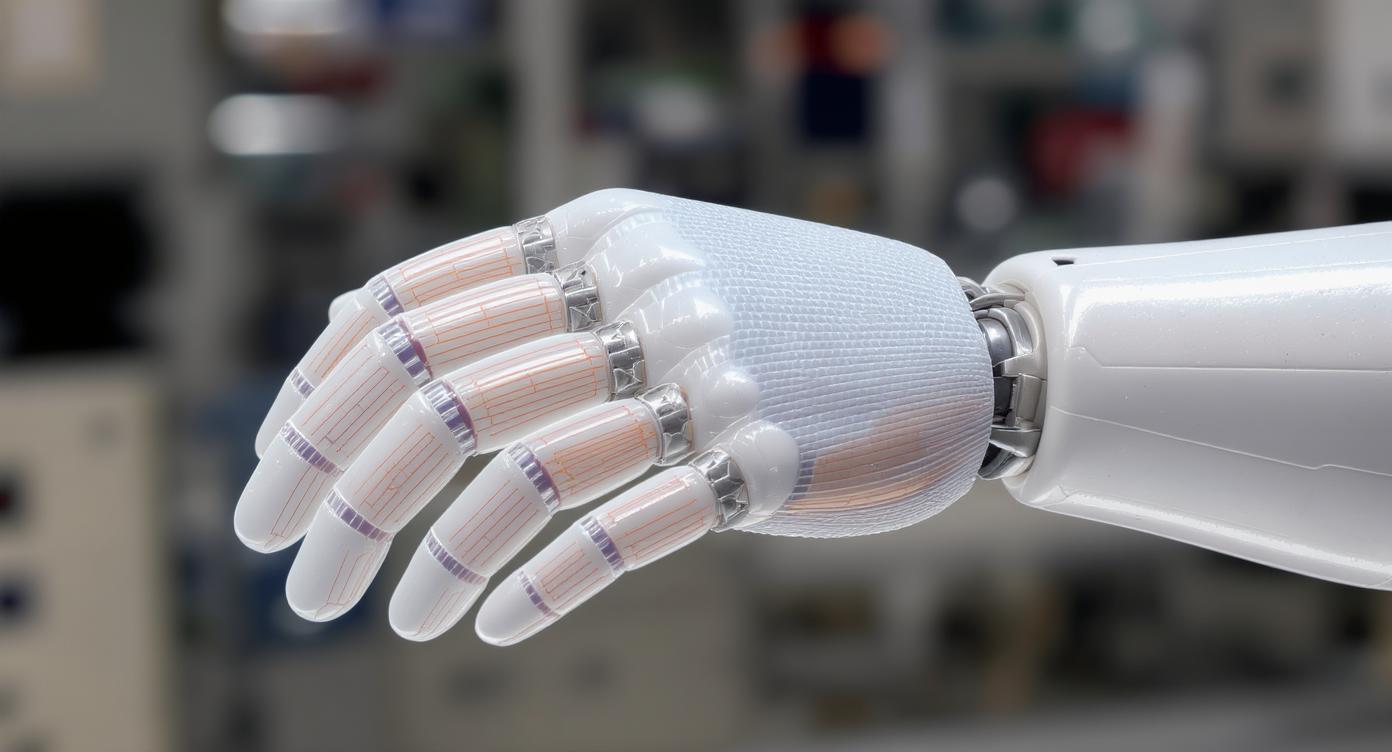

Imagine a robot that flinches away from a hot stove or adjusts its grip to avoid crushing a fragile object. It sounds like science fiction, but recent advances in electronic skin technology are bringing this scenario to life. Researchers at the University of Cambridge and UCL have developed a low-cost, flexible “robot skin” that enables machines to sense touch, temperature, and even potentially painful stimuli in a human-like way. This breakthrough marks a major step toward robots with genuine tactile perception – a development that could transform industries from manufacturing to healthcare.

.

A New Approach to Robotic Touch

Traditional electronic skins typically rely on separate sensors for each sensation – one for pressure, another for temperature, another for vibrations, etc. These patches are then embedded across a surface, which complicates design and can lead to fragile systems (sensors can interfere with each other or wear out easily). The Cambridge-UCL team took a different approach: make the entire skin one single, smart sensor. Their multi-modal electronic skin is made from a soft, electrically conductive hydrogel that can be molded over a robotic limb like a glove. Instead of needing distinct sensor components, this whole material reacts in different ways to different kinds of touch.

Because the skin itself is continuous, every poke, prod, or heat spot creates a unique electrical signal pattern in the gel. By placing just 32 small electrodes at the base of the robotic hand, the researchers can read these signal patterns from across the skin. In fact, the team gathered over 1.7 million data points from those electrodes thanks to the skin’s dense network of 860,000+ microscopic conductive pathways running through the material. This rich data is then analyzed using machine learning algorithms, which train the system to recognize what each pattern means. In tests, the electronic skin learned to distinguish a gentle finger tap from a sharp pinch or a warm touch from an intense heat blast. Essentially, the skin “learns” to interpret stimuli – much like our own nervous system interprets signals from nerves – allowing the robot to tell if it’s being pressed, cut, or burned and respond appropriately.

Notably, the researchers point out that while this artificial skin isn’t yet as exquisitely sensitive as human skin, it’s already more capable than any previous technology in this area. And because it’s made from simple, cheap ingredients (gelatin and salt water, essentially) and one single sensor layer, it’s far easier to produce and more durable than complex multi-sensor assemblies. “Having different sensors for different types of touch leads to materials that are complex to make. We wanted a solution that can detect multiple types of touch at once, but in a single material,” explained Dr. David Hardman, the study’s lead author. His colleague Dr. Thomas Thuruthel added that their method is “flexible and easier to build than traditional sensors”, calibrated using human touch as a reference..

Key Features and Advantages of the New Robot Skin

This innovative electronic skin comes with several impressive features that set it apart from earlier tactile sensors:

- High-Resolution Sensing: The material contains over 860,000 tiny conductive channels, enabling extremely fine sensing resolution across the surface. This means the robot can pinpoint where it’s touched and distinguish different touch events with high precision – whether it’s a light tap, a firm press, or a sharp jab.

- Multi-Modal Touch Detection: Unlike prior solutions that needed separate sensors for pressure, heat, or damage, this single skin can feel pressure, temperature (hot or cold), and even potentially painful stimuli all at once. For example, the robot hand could detect multiple fingers tapping in different spots while also sensing that one spot is painfully hot – simultaneously.

- Flexible and Durable: The skin is made of a cheap, stretchy hydrogel (essentially a gelatin-based material infused with conductive salts) that is both elastic and tough. It can conform to complex shapes – you simply cast it in the shape you need, such as a full glove for a robotic hand. If damaged, the gel-based skin can be melted down and reformed without losing its properties. This makes it easy to repair or reshape for different robots.

- Full Surface Coverage: Because it can be worn “like a glove” over robot appendages, the entire surface becomes a sensing area. There are no blind spots – from fingertip to palm to knuckle, every part of the robotic hand’s surface is alive with sensory input. This omnidirectional coverage gives robots a far more complete awareness of contact, similar to how human skin covers us head-to-toe with touch receptors.

- Human-Like Interaction: With these qualities, robots equipped with the skin can interact with their environment in a more natural, intuitive way. Instead of awkwardly over-gripping objects or failing to notice obstacles, a robot hand can modulate its force and react to stimuli much like a human would. This paves the way for safer human-robot interactions and more “aware” autonomous machines that can adapt to unexpected contact (like feeling a person’s hand and gently letting go, or sensing a hot surface and withdrawing).

From Prosthetics to Rescue: Potential Applications

The capabilities of this technology open up a wide range of applications across different fields. Here are some areas that stand to benefit:

- Humanoid Robots: For robots designed to work alongside people or mimic human behavior, a realistic sense of touch is vital. Humanoid service robots with this skin could shake your hand or handle tools with appropriate force, improving their utility and acceptance in everyday environments. Touch feedback would enable more lifelike and safer reactions, making human-robot interaction feel more seamless and “alive”.

- Advanced Prosthetics: One of the most promising uses is in prosthetic limbs for amputees. A prosthetic hand outfitted with this sensitive skin could let a user feel what they touch – from the warmth of a cup to the pressure needed to hold a pen – dramatically enhancing functionality. Restoring even basic sensations of pressure or temperature can help prosthetic users gain better control and a sense of connection to their environment.

- Automotive Safety: In automobiles or industrial machines, integrating such an electronic skin into surfaces could provide early warnings of problems. For instance, a robotic component in a car assembly line could detect if it’s gripping something off-center or sense overheating parts before they fail. In consumer vehicles, tactile sensors in the interior could improve safety by detecting contact or sudden impacts (acting like an extra sense alongside cameras and radars).

- Disaster Recovery Robots: Search-and-rescue robots working in disaster zones (like earthquake rubble) could use touch sensitivity to find survivors and navigate hazardous debris. A robot snake or rover with this skin could crawl through tight spaces and feel the difference between solid concrete and a softer body, helping locate people trapped under wreckage. The ability to sense pain-like stimuli would also help the robot avoid damaging itself on sharp debris or fire, improving durability in the field.

- Interactive Surfaces and Gaming: Beyond robotics, the technology could inspire touch-responsive smart surfaces. Imagine immersive game controllers or VR gloves covered in this e-skin, letting computers feel your touch and grip – enabling more realistic feedback loops. Interactive art installations or consumer electronics could likewise become more intuitive, responding to how users touch them (for example, a touchscreen that can tell the difference between a gentle swipe and a hard press in a single layer).

When Robots “Feel” Pain: Ethical Questions

Equipping machines with something akin to a sense of touch also raises intriguing ethical and philosophical questions. If a robot can experience a form of pain (i.e. detect harmful stimuli and react to avoid them), does that change how we regard the robot? Of course, a robot’s “pain” is not emotional – it’s a safety response – but as robots start to mimic more human-like sensations, the line between biological and artificial empathy could blur.

We might soon ask: Does a robot that feels pain have rights or moral considerations? For example, would intentionally causing a “feeling” robot to suffer damage be seen as mistreatment? Furthermore, if these sensory machines become commonplace, what responsibilities do their creators have to ensure they're used ethically? As robots gain human-like abilities to sense and potentially even learn from those sensations, society will need to grapple with the question of where the boundary lies between human and machine. Are we simply engineering clever tools, or are we inching toward synthetic beings with experiences of their own? These questions don’t have clear answers yet, but the development of touch-sensitive, responsive robots makes them far more than just science fiction musings.

The Dawn of Sensitive Robots

The advent of robots that can feel their environment marks an exciting turning point in technology. Today, we’re talking about robots that recoil from heat or adjust to a gentle caress; tomorrow we may be dealing with robots that understand and respond to touch in deeply sophisticated ways. This new electronic skin is laying the foundation for machines that interact with the world as naturally as we do.

Beyond the wow-factor, innovations like these highlight just how remarkable the human body really is – our own skin sets an incredibly high bar that scientists are striving to reach. It’s taken years of research and cutting-edge engineering to give a robot a semblance of what living creatures are born with. As we marvel at a future where robots feel pain and warmth, it also gives us a renewed appreciation of our own human touch. In the quest to make machines more like us, we’re reminded of how ingeniously we are made – and that understanding may be the most valuable insight of all.